Services for the installation of water softening systems

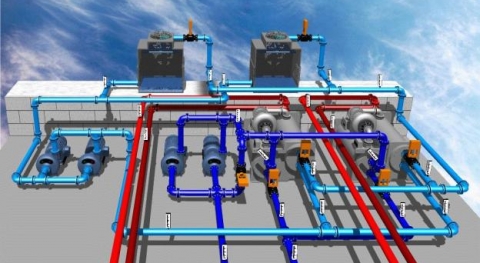

Specializes in designing, constructing the water treatment system hard, hard water softening system for boilers, dross handling systems and anti-corrosion on the pipe.

Needs to use hard water softening system, boiler feed water hard reduction varied

Please contact us to provide you with the best consulting services to meet your requirements.

Hard water is water containing Ca ++ and Mg ++ is higher than the standards allow. Hard water softener for boiler is reducing ion concentrations in order to bring the two standards. Namely 300 mg / l.

Boiler feed water is usually taken from the tap water of industrial parks or water from rivers, streams and wells. The source of this water contains a concentration of Ca 2+ and Mg 2+ (hard water) depending on certain local and regional sources ly.Nuoc hard when it enters the boiler will increasingly denser and not precipitate the air quality tan sticking to the wall of the boiler to reduce heat transfer efficiency of the boiler.

To prevent the creation of fouling in the boiler, the primary method is to thoroughly softened water boiler feed and raise pH to prevent fouling creation process.

Hard water softener mainly based on ion-exchange process, because this process reducing most divalent ions. PH usually caustic alkali hydroxide to give soft water boiler, because if used soda Na2CO3, NaHCO3 them susceptible to hydrolysis in water boilers generate steam and CO2 contamination causes rust effects on the condensate line .

Main equipment:

Shell composite filter columns (select the size according to the capacity of the water column should use).

Autovalve used to control the work process of softening.

Materials used for the softening filter is County ion exchange resin Na + original.

PVC bottle containing saline solution regenerated ion exchange resin beads (Additional sodium for filtration)

Autovalve mains supply is 220V mains operation. Make sure the voltage used for Autovalve stable.Source water softener before crossing the required drinking water standards set by the Ministry of Health regulations. Hot water not exceed 50 ° C input.

Department softeners should be located in a dry place.

PROCESS OPERATING SYSTEM:

Principle of working:

Ministry of water softener works on the process of Autovalve controller, water pump pressure source pushed through Autovalve (input pressure should reach 1.5 - 2.5 bar) into shell particle filtration column containing ion exchange resin, through ion exchange process to remove impurities cause hardness: Calcium, magnesium ... domestic. After a period of operation should use pure salt solution for regeneration of ion exchange resin hat (additional sodium ions)

Process of Autovalve work:

Autovalve operates under five fundamental processes:

The process of filtration (FILTER): domestic ion exchange to remove hardware. Water is used.

Backwashing process (BACKWASH): backwash filter media to clean and remove dirt residue on the filter material and filter inside the casing column. Water will be let go.

The process of regeneration (SLOWRINSE / Brine): slow down rinse à smoking saturated saline solution for regenerating filter material. Water will be let go.

Fast washing process (FASTRINSE): clean filter material again. Water will be let go.Return process water for regeneration salt basin (REFILL): fresh water tank will be taken to dissolve the salt regenerated with saline once again saves water when mixing the salt solution.

(After qu REFILL the end, Autovalve FILTER switch to the normal process)

Resin dirty

regeneration pressure, increase backwash time.

Salt reach the treated water

Needs to use hard water softening system, boiler feed water hard reduction varied

1. The quality of the input water supply system like.

2. Capacity filters to meet the boiler.

3. Demand for water quality after treatment.

4. Ensure the physical and chemical indicators important such as: deposits, metals, pH, total dissolved solids ....

2. Capacity filters to meet the boiler.

3. Demand for water quality after treatment.

4. Ensure the physical and chemical indicators important such as: deposits, metals, pH, total dissolved solids ....

Please contact us to provide you with the best consulting services to meet your requirements.

Hard water is water containing Ca ++ and Mg ++ is higher than the standards allow. Hard water softener for boiler is reducing ion concentrations in order to bring the two standards. Namely 300 mg / l.

Boiler feed water is usually taken from the tap water of industrial parks or water from rivers, streams and wells. The source of this water contains a concentration of Ca 2+ and Mg 2+ (hard water) depending on certain local and regional sources ly.Nuoc hard when it enters the boiler will increasingly denser and not precipitate the air quality tan sticking to the wall of the boiler to reduce heat transfer efficiency of the boiler.

To prevent the creation of fouling in the boiler, the primary method is to thoroughly softened water boiler feed and raise pH to prevent fouling creation process.

Hard water softener mainly based on ion-exchange process, because this process reducing most divalent ions. PH usually caustic alkali hydroxide to give soft water boiler, because if used soda Na2CO3, NaHCO3 them susceptible to hydrolysis in water boilers generate steam and CO2 contamination causes rust effects on the condensate line .

Main equipment:

Shell composite filter columns (select the size according to the capacity of the water column should use).

Autovalve used to control the work process of softening.

Materials used for the softening filter is County ion exchange resin Na + original.

PVC bottle containing saline solution regenerated ion exchange resin beads (Additional sodium for filtration)

Autovalve mains supply is 220V mains operation. Make sure the voltage used for Autovalve stable.Source water softener before crossing the required drinking water standards set by the Ministry of Health regulations. Hot water not exceed 50 ° C input.

Department softeners should be located in a dry place.

PROCESS OPERATING SYSTEM:

Principle of working:

Ministry of water softener works on the process of Autovalve controller, water pump pressure source pushed through Autovalve (input pressure should reach 1.5 - 2.5 bar) into shell particle filtration column containing ion exchange resin, through ion exchange process to remove impurities cause hardness: Calcium, magnesium ... domestic. After a period of operation should use pure salt solution for regeneration of ion exchange resin hat (additional sodium ions)

Process of Autovalve work:

Autovalve operates under five fundamental processes:

The process of filtration (FILTER): domestic ion exchange to remove hardware. Water is used.

Backwashing process (BACKWASH): backwash filter media to clean and remove dirt residue on the filter material and filter inside the casing column. Water will be let go.

The process of regeneration (SLOWRINSE / Brine): slow down rinse à smoking saturated saline solution for regenerating filter material. Water will be let go.

Fast washing process (FASTRINSE): clean filter material again. Water will be let go.Return process water for regeneration salt basin (REFILL): fresh water tank will be taken to dissolve the salt regenerated with saline once again saves water when mixing the salt solution.

(After qu REFILL the end, Autovalve FILTER switch to the normal process)

Resin dirty

regeneration pressure, increase backwash time.

Salt reach the treated water

- Injector clogged

- Watches inactive

- Salt intake valve clogged

- Salt clogged suction line

- Hygiene injector replacement nets

- Rather watch

- Cleaning sine

Maybe you care

Ý kiến bạn đọc: